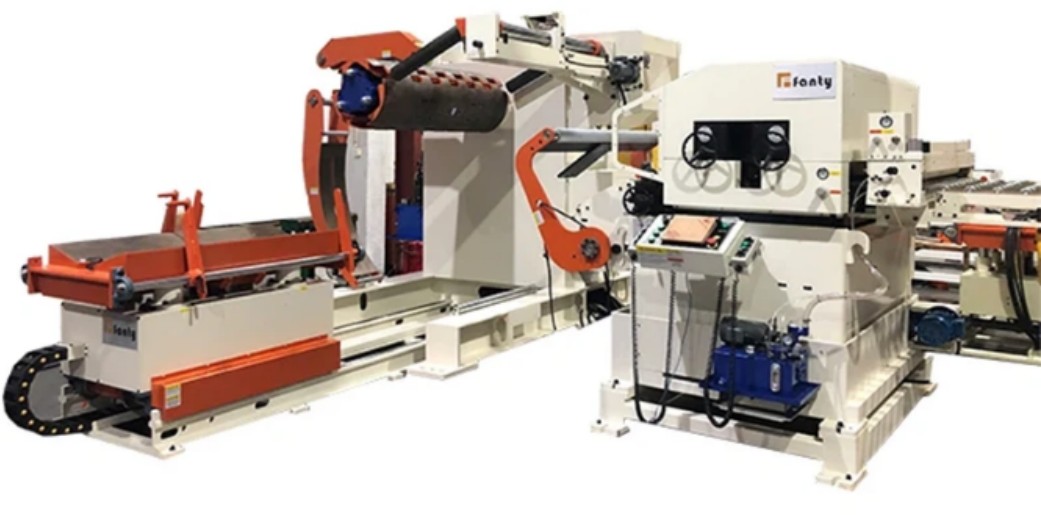

Coil handling equipments as the backbone of efficient steel processing industries, streamlining operations and enhancing productivity. From unwinding to feeding, straightening to cutting, coil handling equipment plays a pivotal role in managing the intricate processes involved in steel fabrication. In this comprehensive guide, we delve into the depths of coil handling equipment, exploring its functions, types, and the pivotal role it plays in the steel industry.

Understanding Coil Handling Equipment

Steel handling equipments refers to a diverse range of machinery designed to handle coils of various sizes and materials, predominantly steel. These equipments are essential for industries involved in metal fabrication, automotive manufacturing, construction, and many others where steel handling plays a crucial role.

Types of Coil Handling Equipment

- Decoilers and Uncoilers: These machines are responsible for unwinding coils, effectively preparing them for further processing. Decoilers come in various sizes and configurations to accommodate different coil dimensions and weights. They ensure a smooth and controlled unwinding process, minimizing downtime and maximizing efficiency.

- Straighteners: Coil straighteners play a vital role in ensuring the flatness and uniformity of steel coils. By eliminating any distortions or irregularities, straighteners prepare the material for subsequent processing steps such as cutting or stamping. Modern straightening machines utilize advanced technology to achieve precise results while minimizing material waste.

- Feeding Equipment: Once the coils are unwound and straightened, feeding equipment comes into play to accurately convey the material to the next stage of production. Whether it’s a roll feeder, servo feeder, or pneumatic feeder, these machines ensure a continuous and controlled feed of steel, optimizing the efficiency of downstream processes.

- Cut-to-Length Lines: Cut-to-length lines are integral for precision cutting of steel coils into specified lengths. These lines consist of various components such as leveling machines, shears, and stacking systems, working in harmony to deliver accurate and consistent cuts. Cut-to-length lines are widely used in industries requiring customized steel products with precise dimensions.

Applications of Coil Handling Equipment

The versatility of coil handling equipment enables its application across a wide range of industries and processes. Here are some notable applications:

- Automotive Manufacturing: Coil handling equipment is extensively used in the automotive industry for producing components such as chassis, body panels, and structural parts. The efficiency and precision offered by these machines are crucial for meeting the stringent quality standards and production demands of the automotive sector.

- Metal Fabrication: In metal fabrication facilities, coil handling equipment is indispensable for processing raw materials into finished products. Whether it’s cutting, bending, or stamping, these machines ensure the seamless flow of materials through various production stages, optimizing throughput and minimizing waste.

- Appliance Production: Coil handling equipment plays a vital role in the production of household appliances such as refrigerators, washing machines, and HVAC systems. From shaping metal sheets to forming intricate components, these machines contribute to the efficient manufacturing of durable and high-quality appliances.

- Construction Industry: Steel is a fundamental material in the construction industry, and coil handling equipment facilitates the fabrication of structural components, roofing panels, and reinforcing elements. The speed and accuracy offered by these machines are essential for meeting project timelines and adhering to construction specifications.

Benefits of Coil Handling Equipment

- Increased Efficiency: By automating labor-intensive processes and minimizing manual intervention, coil handling equipment enhances overall operational efficiency. Reduced setup times, faster processing speeds, and consistent output contribute to higher productivity levels.

- Improved Safety: Manual handling of heavy steel coils poses significant safety risks to workers. Coil handling equipment mitigates these risks by mechanizing tasks such as lifting, feeding, and straightening, thereby creating a safer work environment and reducing the likelihood of accidents.

- Enhanced Precision: Modern coil handling equipment is equipped with advanced technologies such as servo controls, laser measurement systems, and programmable logic controllers (PLCs) that ensure precise control over processing parameters. This precision results in higher product quality and tighter tolerances.

- Cost Savings: While the initial investment in coil handling equipment may seem substantial, the long-term cost savings are considerable. By minimizing material waste, optimizing energy consumption, and reducing downtime, these machines contribute to significant cost reductions over their lifespan.

Future Trends in Coil Handling Equipment

As industries continue to evolve and demand for steel products grows, the coil handling equipment sector is poised for innovation and advancement. Some emerging trends include:

- Integration of Industry 4.0 Technologies: The integration of IoT (Internet of Things), AI (Artificial Intelligence), and predictive analytics is transforming coil handling equipment into smart and connected systems. Real-time monitoring, predictive maintenance, and data-driven decision-making are becoming standard features, enhancing operational efficiency and uptime.

- Customization and Flexibility: With the increasing demand for customized steel products, coil handling equipment manufacturers are focusing on providing modular and flexible solutions. Quick changeover capabilities, adjustable settings, and compatibility with various coil sizes enable manufacturers to adapt swiftly to changing market demands.

- Energy Efficiency: Energy consumption is a significant concern in manufacturing operations, and coil handling equipment is no exception. Future developments in energy-efficient motors, hydraulic systems, and regenerative braking technologies will prioritize sustainability while maintaining high levels of productivity.

Conclusion

Coil handling equipment stands as an indispensable component of the steel industry, enabling efficient processing of raw materials into finished products. From unwinding to feeding, straightening to cutting, these machines play a crucial role in streamlining production processes, enhancing quality, and improving safety. With ongoing technological advancements and a focus on innovation, coil handling equipment will continue to drive efficiency and productivity in the ever-evolving landscape of steel manufacturing.