Laser transfer or thermal transfer is one of the most popular methods of transferring an image to various surfaces using an intermediate carrier thermal transfer paper and a thermal press. To start making thermal transfer, you need the following equipment and materials:

- Computer or laptop: On which you set the image you need (logo, photo or any other picture or inscription).

- Color laser printer or copier.

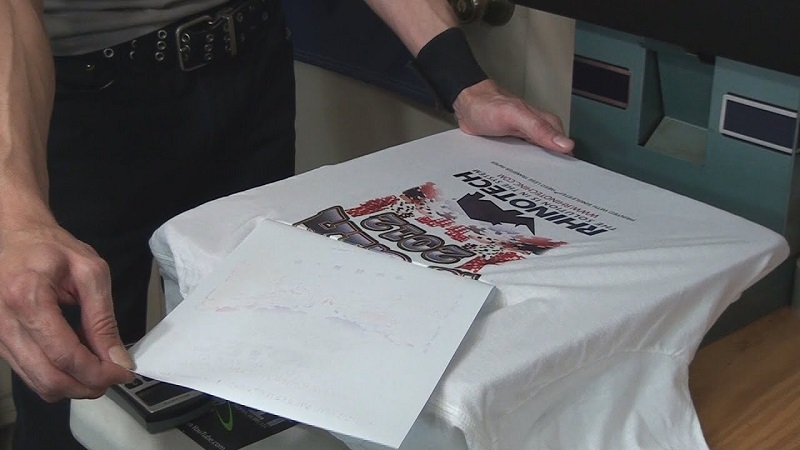

Before printing an image on a laser printer or copier, you should know in advance on what material and with what paper the transfer will be carried out. If it is light cotton textiles white or light T-shirts, baseball caps, etc., as well as any flat hard surfaces, then print the image in a mirror image. If it is dark or black cotton textiles dark or black cotton T-shirts, baseball caps, etc., then print the image directly.

Thermal transfer paper

The laser transfer paper is the medium that transfers the toner to the desired material. Correct selection of thermal transfer paper is very important. First, choose the right paper for the type of printer or copier. The main difference between printers in this case is the use of fuser oil or its absence which makes the printer high-temperature. Therefore, we wonder if the printer is high temperature and oil-free, or if it works with fuser oil. As a rule, printers with fuser oil are more productive A3 format models of the older generation.

Modern models, especially A4 format, are oil-free. Fuser oil printers are less moody and work reasonably well with different types of transfer papers. It can be more difficult to select paper for high-temperature printers, because if the wrong paper is used, it can stick, solder to the shaft, thereby ruining it, which is highly undesirable. Secondly, choose the right paper depending on the material on which you plan to transfer the image.

The main difference between paper is the structural and color difference of the materials to which the transfer is carried out. It is easier to transfer a color image to light and white fabric, because the surface itself is light, which makes the applied image visible on it and bright. When transferred with this paper, toner and a thin layer of translucent glue are transferred to the material, which fixes it.

With dark and black fabric, the situation is more complicated light colors with standard transfer on a dark surface will either not be visible at all or will look faded. Therefore, in this case, paper on a white backing is used. A kind of sandwich effect is created; when transferred, a white opaque substrate with an image printed on top is glued onto the fabric. In this case, the picture itself looks denser and harder, but the colors are brighter and more saturated.

Thermal transfer press

The thermal transfer press is selected depending on the surface to which the image is to be transferred. If it is a flat surface (T-shirts, various fabrics, metal plates, tiles, mouse pads, puzzles, etc.) you need a flat thermal transfer press. The flat press can be hinged (the upper one, the heating plate swings up) or swivel (the upper one, the heating plate is lifted up and moved to the side). The rotary heat press is more convenient to operate, because the heat from the top plate does not go directly to the printer. Plus, the rotary press, due to its design, makes it possible to seal thicker products (for example, jackets, overalls, etc.).